Graphite Electrodes Uses Steelmaking With Nipples RP HP UHP20 Inch

Technical Parameter

|

Parameter |

Part |

Unit |

RP 500mm(20”) Data |

|

Nominal Diameter |

Electrode |

mm(inch) |

500 |

|

Max Diameter |

mm |

511 |

|

|

Min Diameter |

mm |

505 |

|

|

Nominal Length |

mm |

1800/2400 |

|

|

Max Length |

mm |

1900/2500 |

|

|

Min Length |

mm |

1700/2300 |

|

|

Max Current Density |

KA/cm2 |

13-16 |

|

|

Current Carrying Capacity |

A |

25000-32000 |

|

|

Specific Resistance |

Electrode |

μΩm |

7.5-8.5 |

|

Nipple |

5.8-6.5 |

||

|

Flexural Strength |

Electrode |

Mpa |

≥8.5 |

|

Nipple |

≥16.0 |

||

|

Young’s Modulus |

Electrode |

Gpa |

≤9.3 |

|

Nipple |

≤13.0 |

||

|

Bulk Density |

Electrode |

g/cm3 |

1.55-1.64 |

|

Nipple |

≥1.74 |

||

|

C.T.E. |

Electrode |

×10-6/℃ |

≤2.4 |

|

Nipple |

≤2.0 |

||

|

Ash Content |

Electrode |

% |

≤0.3 |

|

Nipple |

≤0.3 |

NOTE:Any specific requirement on dimension can be offered.

RP Graphite Electrode Advantage

- High current carrying capacity.

- High resistance to oxidation and thermal shock.

- Outstanding resistance to breakage.

- Good dimension stability, not easy to deform.

- High machining accuracy, good surface finishing.

- High mechanical strength, low electrical resistance.

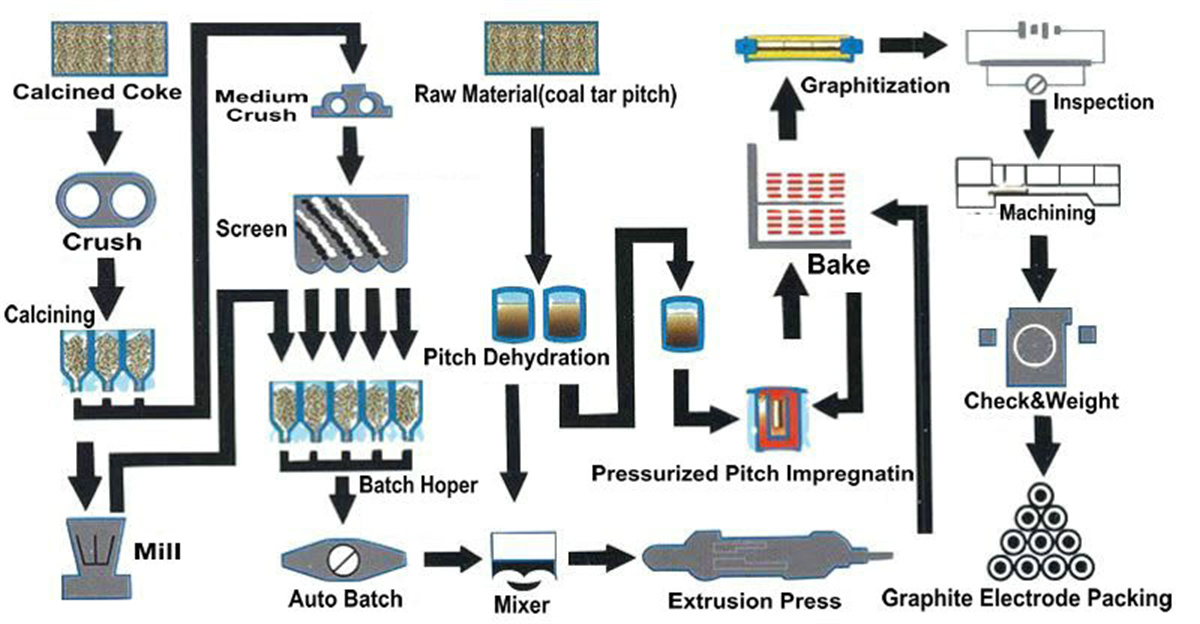

RP Graphite Electrode Production Process

It usually needs about 20days- 45 days after receiving the deposit.

We are packed in wooden cases/pallets with steel strips, or according to your requirements.

Send us inquiry e-mail, we will contact with you when we receive your email, or contact me on chat app.

Gufan Carbon graphite electrodes have the advantages of low resistivity, high electrical and thermal conductivity, good oxidation resistance, good thermal shock resistance, high mechanical strength. We can supply widely range of products from the diamater 200mm to diameter 700mm,including UHP,HP,RP grade graphite electrode.Also supply OEM and ODM service to satisfied all customers.