UHP 350mm Graphite Electrodes In Electrolysis For Smelting Steel

Technical Parameter

|

Parameter |

Part |

Unit |

UHP 350mm(14”) Data |

|

Nominal Diameter |

Electrode |

mm(inch) |

350(14) |

|

Max Diameter |

mm |

358 |

|

|

Min Diameter |

mm |

352 |

|

|

Nominal Length |

mm |

1600/1800 |

|

|

Max Length |

mm |

1700/1900 |

|

|

Min Length |

mm |

1500/1700 |

|

|

Max Current Density |

KA/cm2 |

20-30 |

|

|

Current Carrying Capacity |

A |

20000-30000 |

|

|

Specific Resistance |

Electrode |

μΩm |

4.8-5.8 |

|

Nipple |

3.4-4.0 |

||

|

Flexural Strength |

Electrode |

Mpa |

≥12.0 |

|

Nipple |

≥22.0 |

||

|

Young’s Modulus |

Electrode |

Gpa |

≤13.0 |

|

Nipple |

≤18.0 |

||

|

Bulk Density |

Electrode |

g/cm3 |

1.68-1.72 |

|

Nipple |

1.78-1.84 |

||

|

C.T.E. |

Electrode |

×10-6/℃ |

≤1.2 |

|

Nipple |

≤1.0 |

||

|

Ash Content |

Electrode |

% |

≤0.2 |

|

Nipple |

≤0.2 |

NOTE:Any specific requirement on dimension can be offered.

Product Grade

Graphite electrode grades are divided into regular power graphite electrode(RP), high power graphite electrode( HP), ultra high power graphite electrode(UHP).

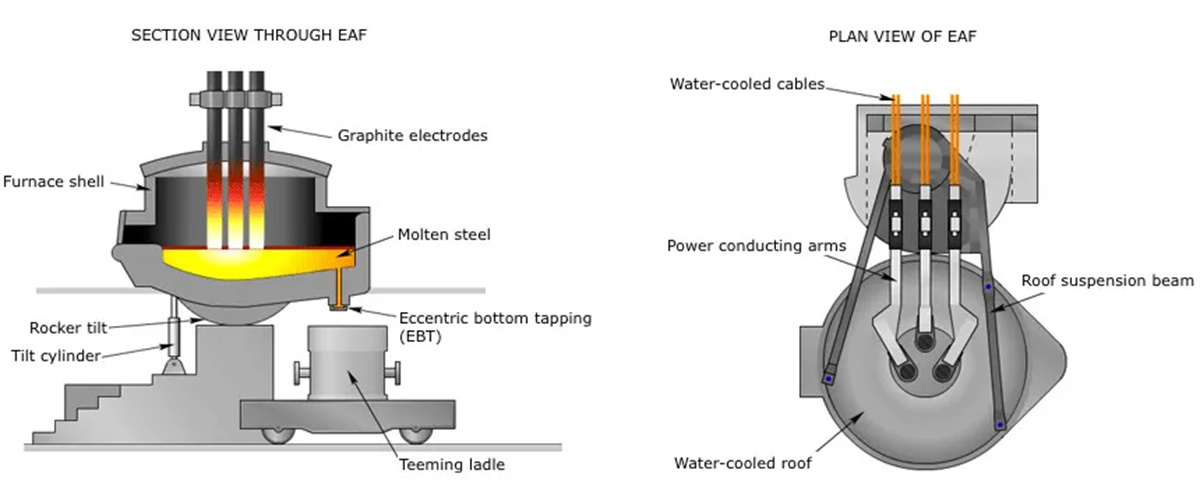

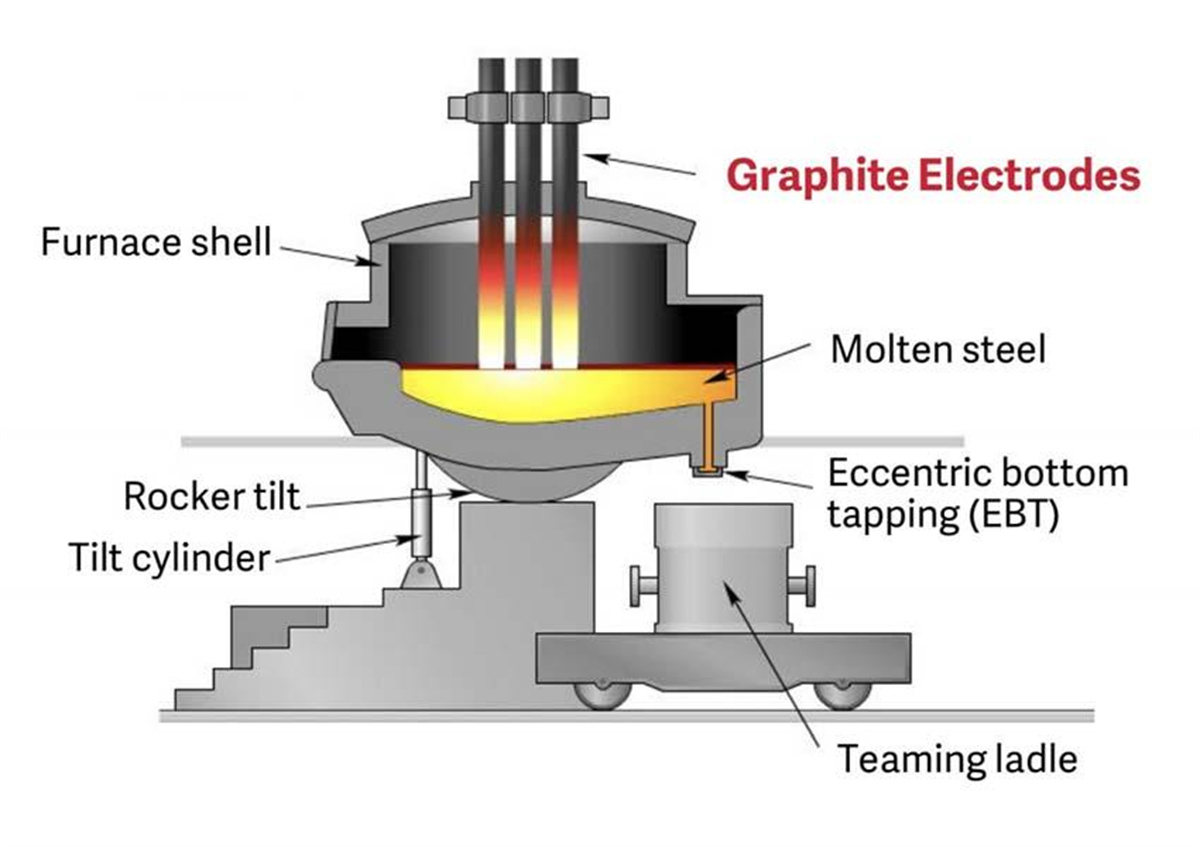

Mainly Application For Electric Arc Furnace In Steel Making

Graphite electrodes for steel making accounts for 70-80% of the total amount of graphite electrodes application. By passing a high voltage and current to graphite electrode, electric arc will be generated between electrode tip and metal scrap which will produce huge heat to melt the scrap. The process of smelting will consume the graphite electrode, and they have to be replaced constantly.

UHP graphite electrode is commonly used in the steel industry during the production of electric arc furnace (EAF) steel. The EAF process involves melting down scrap steel to produce new steel. The UHP graphite electrode is used to create an electric arc, which heats the scrap steel to its melting point. This process is efficient and cost-effective, as it allows the steel to be produced quickly and in large quantities.

Section View and Plan View of Electrical Arc Furnace

We are the manufacture owned complete production line and professional team.

30% TT in advance as down payment,The 70% balance TT before delivery.