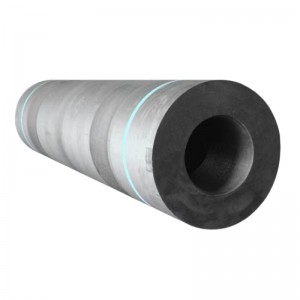

RP 600mm 24inch Graphite Electrode For EAF LF Smelting Steel

Technical Parameter

|

Parameter |

Part |

Unit |

RP 600mm(24”) Data |

|

Nominal Diameter |

Electrode |

mm(inch) |

600 |

|

Max Diameter |

mm |

613 |

|

|

Min Diameter |

mm |

607 |

|

|

Nominal Length |

mm |

2200/2700 |

|

|

Max Length |

mm |

2300/2800 |

|

|

Min Length |

mm |

2100/2600 |

|

|

Max Current Density |

KA/cm2 |

11-13 |

|

|

Current Carrying Capacity |

A |

30000-36000 |

|

|

Specific Resistance |

Electrode |

μΩm |

7.5-8.5 |

|

Nipple |

5.8-6.5 |

||

|

Flexural Strength |

Electrode |

Mpa |

≥8.5 |

|

Nipple |

≥16.0 |

||

|

Young’s Modulus |

Electrode |

Gpa |

≤9.3 |

|

Nipple |

≤13.0 |

||

|

Bulk Density |

Electrode |

g/cm3 |

1.55-1.64 |

|

Nipple |

≥1.74 |

||

|

C.T.E. |

Electrode |

×10-6/℃ |

≤2.4 |

|

Nipple |

≤2.0 |

||

|

Ash Content |

Electrode |

% |

≤0.3 |

|

Nipple |

≤0.3 |

NOTE:Any specific requirement on dimension can be offered.

How To Maintenance For Graphite Electrode

In addition to selecting the right RP graphite electrode, maintenance is essential to ensure the longevity and efficiency of the electrode. Proper handling and storage of the electrode are crucial to minimize the risk of electrode oxidation, sublimation, dissolution, spalling, and breakage. When the electrode is being used, the furnace operator should pay attention to the electrode's wear and tear and adjust the electrode's position and power input accordingly. Proper post-maintenance inspection, including visual inspection and electrical conductivity testing, can also help identify any potential damage or deterioration of the electrode.

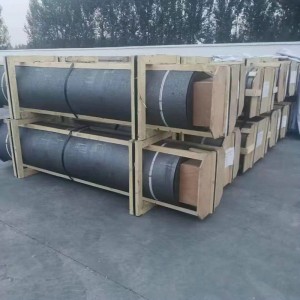

Instruction Handing And Using For Graphite Electrodes

- Use the special lifting tools to life the graphite electrode avoid damaged during transportation.(see pic1)

- Graphite electrode must be kept away from being moistened or wet by rain,snow,be kept dry.(see pic2)

- Carefully checking before use ensure the socket and nipple thread is suitable for use,including inspection for pitch,plug.(see pic3)

- Clean the nipple and sockets threads by compressed air.(see pic4)

- Before use,the graphite electrode must be dried in the furnace,the drying temperature should be less than 150℃,the dried time should be more than 30hours.(see pic5)

- Graphite electrode must be connected tightly and straightly with suitable tightening torque.(see pic6)

- To avoid the graphite electrode breakage,put the large part in lower position and small part in the upper position.

RP Graphite Electrode Current Carrying Capacity Chart

| Nominal Diameter |

Regular Power(RP) Grade Graphite Electrode |

||

|

mm |

Inch |

Current Carrying Capacity(A) |

Current Density(A/cm2) |

|

300 |

12 |

10000-13000 |

14-18 |

|

350 |

14 |

13500-18000 |

14-18 |

|

400 |

16 |

18000-23500 |

14-18 |

|

450 |

18 |

22000-27000 |

13-17 |

|

500 |

20 |

25000-32000 |

13-16 |

|

550 |

22 |

28000-36000 |

12-15 |

|

600 |

24 |

30000-36000 |

11-13 |