Guidance On Handling, Transportation, Storage For Graphite Electrodes

Graphite electrodes are the backbone of the steelmaking industry. These highly efficient and durable electrodes are critical in the production of steel, also they are used for electric arc furnace melting and refining in various industrial applications. We understand the importance of ensuring the proper usage and storage of electrodes to ensure their longevity and effectiveness,finally reduce graphite electrode’s consumption and improve the economic efficiency of factories.

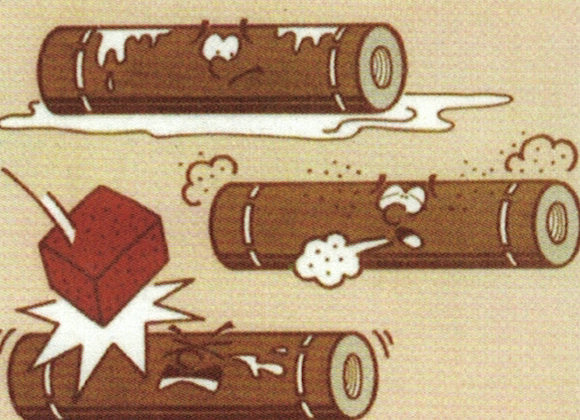

Note1:Using or stocking electrodes,avoid moisture,dust and dirt, avoid collisions lead to electrode damage.

Note2:Using a forklift to transport the electrode. Overloading and collisions are strictly prohibited, and attention should be paid to balance to prevent slipping and breaking.

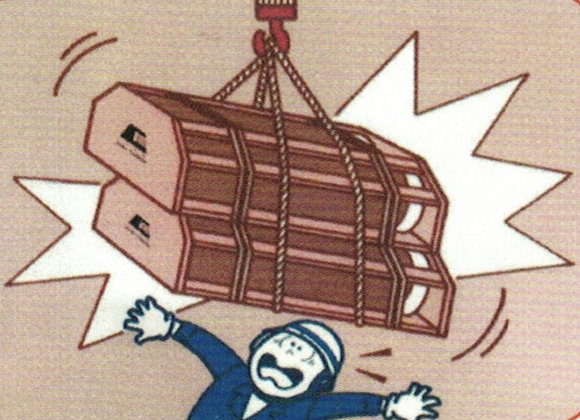

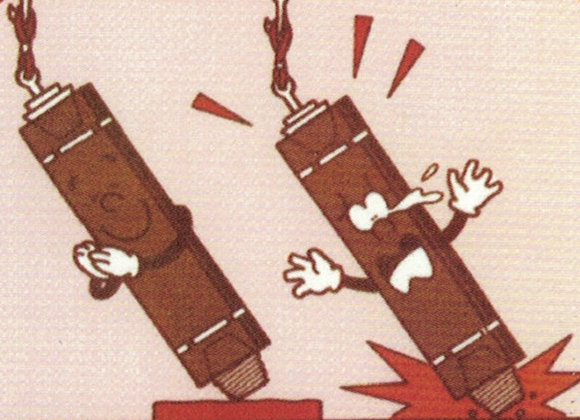

Note3:During loading and unloading with a bridge crane, the operator must obey the commands given. It is imperative to avoid standing under the lifting rack to avoid accidents.

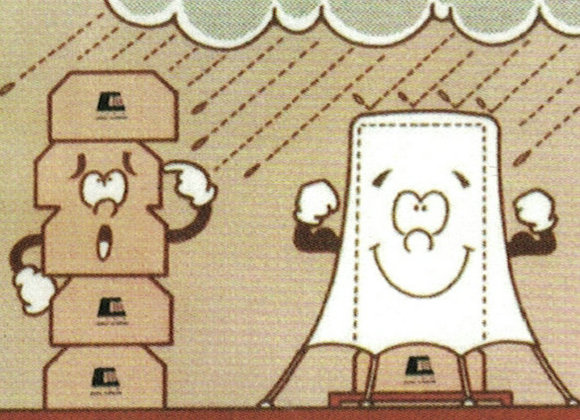

Note4:Store the electrode in a clean and dry place, and when stacked in the open field, it must be covered with a rainproof tarpaulin.

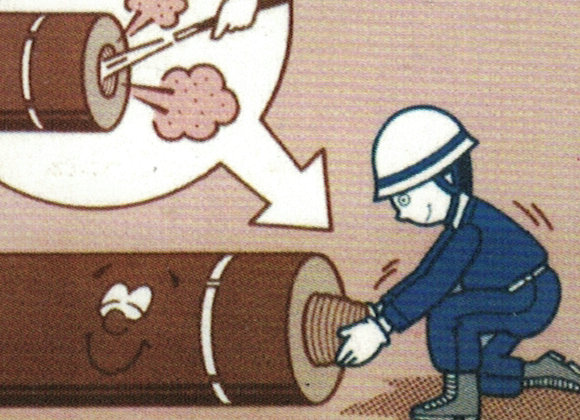

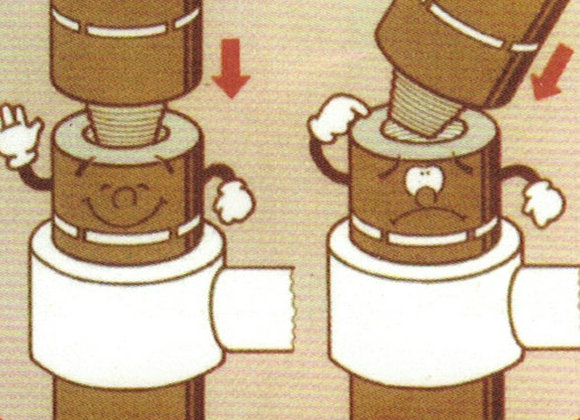

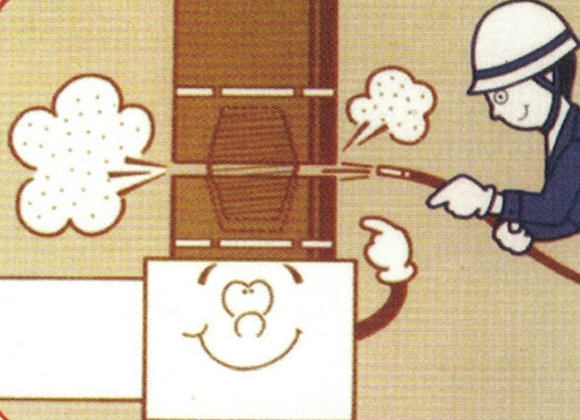

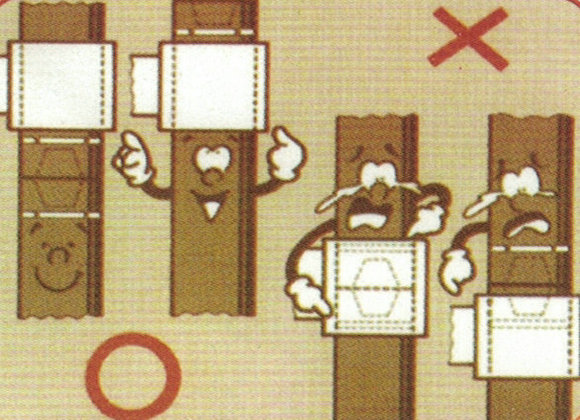

Note5:Before connecting the electrode, blow off the thread of the electrode with compressed air before carefully screwing in the joint into one end. Screw the lifting bolt of the electrode into the other end without hitting the thread.

Note6:When lifting the electrode, use a rotatable hook and place a soft support pad under the electrode connector to prevent damage to the thread.

Note7:Always use compressed air to clean the hole before connecting the electrode.

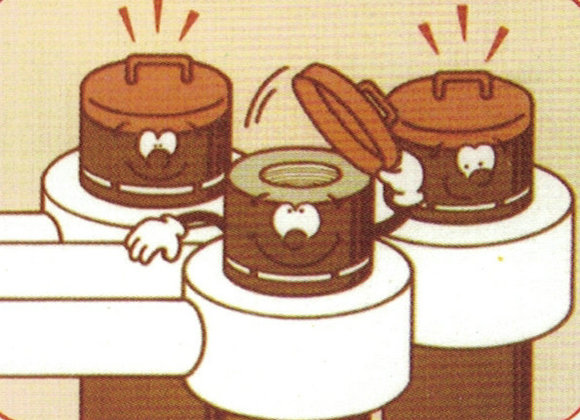

Note8:When lifting the electrode to the furnace using an elastic hook hoist, always find the center, and move down slowly.

Note9:Blow off the electrode junction with compressed air when the upper electrode is lowered to a distance of 20-30 meters from the lower electrode.

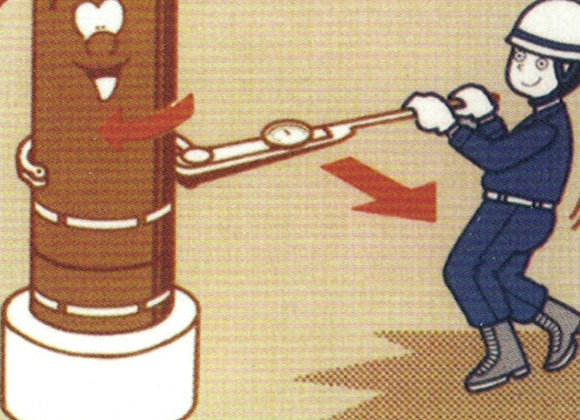

Note10:Use a recommended torque wrench to tighten the recommended torque in the table below. It can be tightened to the specified torque by mechanical means or hydraulic air pressure equipment.

Note11:The electrode holder must be clamped within the two white warning lines. The contact surface between the holder and the electrode should be cleaned frequently to maintain good contact with the electrode. The cold water jacket of the holder is strictly prohibited from leaking.

Note12:Cover the top of the electrode to avoid oxidation and dust on the top.

Note13:No insulating material should be placed in the furnace, and the working current of the electrode should be compatible with the allowable current of the electrode in the manual.

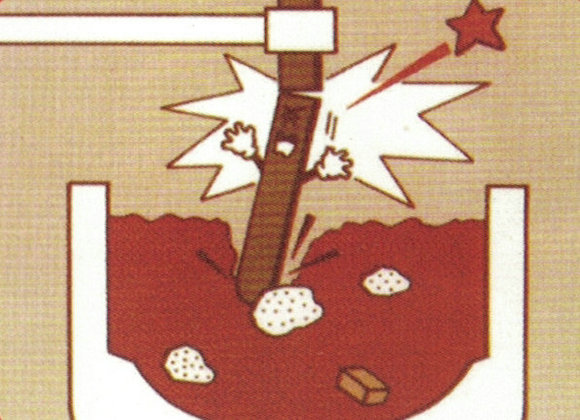

Note14:To avoid electrode breaking, place the large material in the lower part and install the small material in the upper part.

With proper handling, transportation, and storage, our electrodes will serve you for longer and efficiently. Get in touch with us for all your graphite electrode needs, and we will provide the support and expertise needed for smooth operations.

Graphite Electrode Recommended Joint Torque Chart

|

Electrode Diameter |

Torque |

Electrode Diameter |

Torque |

||||

|

inch |

mm |

ft-lbs |

N·m |

inch |

mm |

ft-lbs |

N·m |

|

12 |

300 |

480 |

650 |

20 |

500 |

1850 |

2500 |

|

14 |

350 |

630 |

850 |

22 |

550 |

2570 |

3500 |

|

16 |

400 |

810 |

1100 |

24 |

600 |

2940 |

4000 |

|

18 |

450 |

1100 |

1500 |

28 |

700 |

4410 |

6000 |

| Note: When connecting two poles of electrode,avoid over pressure for electrode and cause bad effect.Please refer to the rated torque in the above chart. | |||||||

Post time: Apr-10-2023