UHP 450mm Furnace Graphite Electrodes With Nipples T4L T4N 4TPI

Technical Parameter

|

Parameter |

Part |

Unit |

UHP 450mm(18”) Data |

|

Nominal Diameter |

Electrode |

mm(inch) |

450(18) |

|

Max Diameter |

mm |

460 |

|

|

Min Diameter |

mm |

454 |

|

|

Nominal Length |

mm |

1800/2400 |

|

|

Max Length |

mm |

1900/2500 |

|

|

Min Length |

mm |

1700/2300 |

|

|

Max Current Density |

KA/cm2 |

19-27 |

|

|

Current Carrying Capacity |

A |

32000-45000 |

|

|

Specific Resistance |

Electrode |

μΩm |

4.8-5.8 |

|

Nipple |

3.4-3.8 |

||

|

Flexural Strength |

Electrode |

Mpa |

≥12.0 |

|

Nipple |

≥22.0 |

||

|

Young’s Modulus |

Electrode |

Gpa |

≤13.0 |

|

Nipple |

≤18.0 |

||

|

Bulk Density |

Electrode |

g/cm3 |

1.68-1.72 |

|

Nipple |

1.78-1.84 |

||

|

C.T.E. |

Electrode |

×10-6/℃ |

≤1.2 |

|

Nipple |

≤1.0 |

||

|

Ash Content |

Electrode |

% |

≤0.2 |

|

Nipple |

≤0.2 |

NOTE:Any specific requirement on dimension can be offered.

Applications

The ultra high power(UHP) graphite electrodes are used in Electric Arc Furnace applications producing high-quality steel and other metals. Also are widely used in a variety of industries,including nuclear power, metallurgy, chemicals, and more.The UHP Graphite Electrode is also known for its high mechanical strength and machining accuracy. This ensures that the graphite electrodes are strong enough to withstand the intense forces and pressures inside the furnace, while maintaining their shape and size. Gufan is devoting to produce a widely range of UHP graphite electrode to meet the requirement of higher work efficiency and low total cost for all world customers.

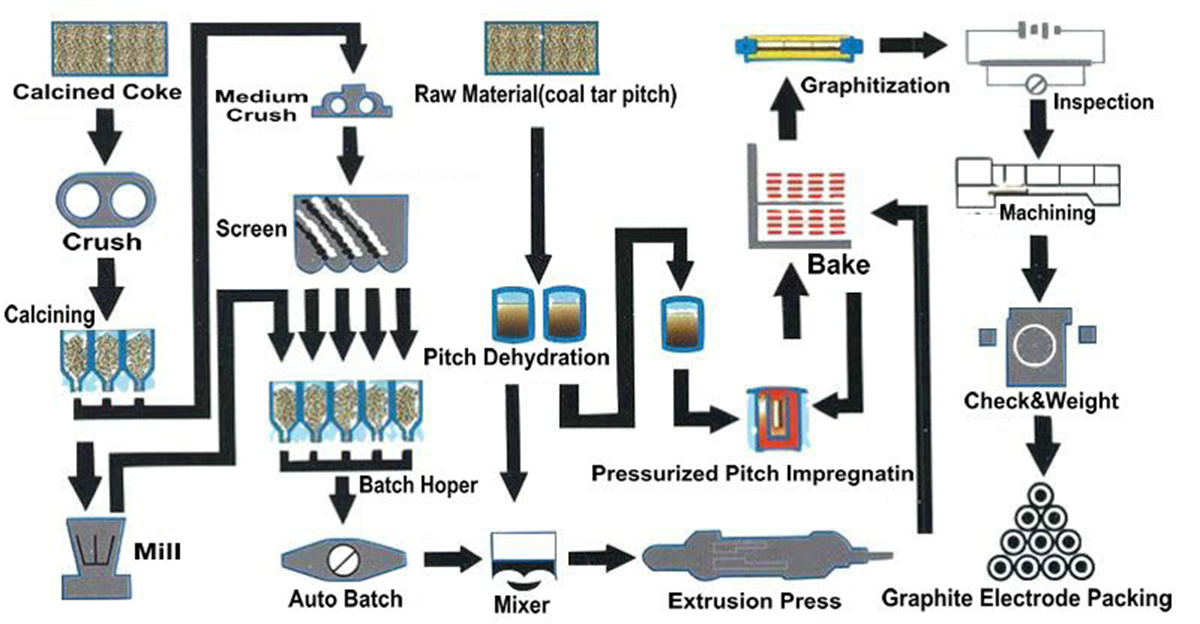

Production Process Chart

Send us inquiry e-mail, we will contact with you when we receive your email, or contact me on chat app.

Yes, we do. The shipping mark can be designed and printed as your requirement.

Usually the delivery time is 10 to 15 days after payment or signing the contract. Or the delivery time can be negotiated if you need to deliver monthly or other special time.