Graphite Electrodes Nipples 3tpi 4tpi Connecting Pin T3l T4l

Description

The graphite electrode nipple is a small but essential part of the EAF steelmaking process. It is a cylindrical-shaped component that connects the electrode to the furnace. During the steelmaking process, the electrode is lowered into the furnace and placed in contact with the molten metal. Electrical current flows through the electrode, generating heat, which melts the metal in the furnace. The nipple plays a crucial role in maintaining a stable electrical connection between the electrode and the furnace.

Technical Parameter

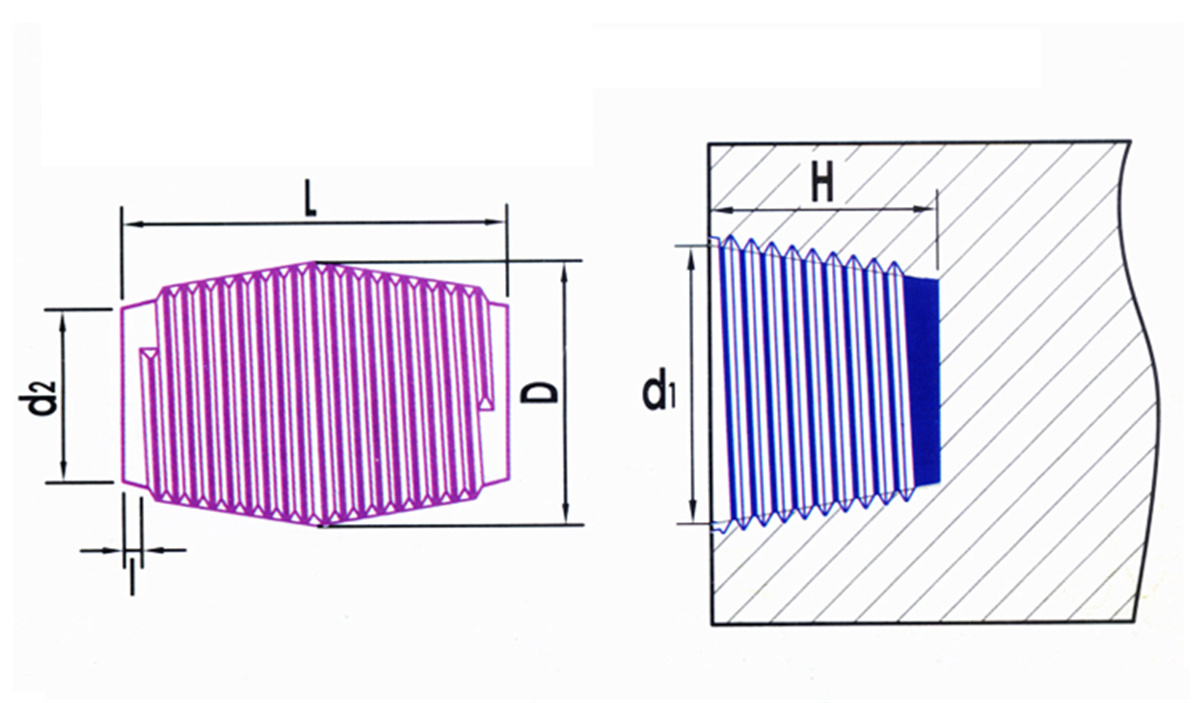

Gufan Carbon Conical Nipple and Socket Drawing

|

Nominal Diameter |

IEC Code |

Sizes of Nipple (mm) |

Sizes of Socket(mm) |

Pitch |

|||||

|

mm |

inch |

D |

L |

d2 |

I |

d1 |

H |

mm |

|

|

Tolerance (-0.5~0) |

Tolerance (-1~0) |

Tolerance (-5~0) |

Tolerance (0~0.5) |

Tolerance (0~7) |

|||||

|

200 |

8 |

122T4N |

122.24 |

177.80 |

80.00 |

<7 |

115.92 |

94.90 |

6.35 |

|

250 |

10 |

152T4N |

152.40 |

190.50 |

108.00 |

146.08 |

101.30 |

||

|

300 |

12 |

177T4N |

177.80 |

215.90 |

129.20 |

171.48 |

114.00 |

||

|

350 |

14 |

203T4N |

203.20 |

254.00 |

148.20 |

196.88 |

133.00 |

||

|

400 |

16 |

222T4N |

222.25 |

304.80 |

158.80 |

215.93 |

158.40 |

||

|

400 |

16 |

222T4L |

222.25 |

355.60 |

150.00 |

215.93 |

183.80 |

||

|

450 |

18 |

241T4N |

241.30 |

304.80 |

177.90 |

234.98 |

158.40 |

||

|

450 |

18 |

241T4L |

241.30 |

355.60 |

169.42 |

234.98 |

183.80 |

||

|

500 |

20 |

269T4N |

269.88 |

355.60 |

198.00 |

263.56 |

183.80 |

||

|

500 |

20 |

269T4L |

269.88 |

457.20 |

181.08 |

263.56 |

234.60 |

||

|

550 |

22 |

298T4N |

298.45 |

355.60 |

226.58 |

292.13 |

183.80 |

||

|

550 |

22 |

298T4L |

298.45 |

457.20 |

209.65 |

292.13 |

234.60 |

||

|

600 |

24 |

317T4N |

317.50 |

355.60 |

245.63 |

311.18 |

183.80 |

||

|

600 |

24 |

317T4L |

317.50 |

457.20 |

228.70 |

311.18 |

234.60 |

||

|

650 |

26 |

355T4N |

355.60 |

457.20 |

266.79 |

349.28 |

234.60 |

||

|

650 |

26 |

355T4L |

355.60 |

558.80 |

249.66 |

349.28 |

285.40 |

||

|

700 |

28 |

374T4N |

374.65 |

457.20 |

285.84 |

368.33 |

234.60 |

||

|

700 |

28 |

374T4L |

374.65 |

558.80 |

268.91 |

368.33 |

285.40 |

||

|

Nominal Diameter |

IEC Code |

Sizes of Nipple (mm) |

Sizes of Socket(mm) |

Pitch |

|||||

|

mm |

inch |

D |

L |

d2 |

I |

d1 |

H |

mm |

|

|

Tolerance (-0.5~0) |

Tolerance (-1~0) |

Tolerance (-5~0) |

Tolerance (0~0.5) |

Tolerance (0~7) |

|||||

|

250 |

10 |

155T3N |

155.57 |

220.00 |

103.80 |

<7 |

147.14 |

116.00 |

8.47 |

|

300 |

12 |

177T3N |

177.16 |

270.90 |

116.90 |

168.73 |

141.50 |

||

|

350 |

14 |

215T3N |

215.90 |

304.80 |

150.00 |

207.47 |

158.40 |

||

|

400 |

16 |

241T3N |

241.30 |

338.70 |

169.80 |

232.87 |

175.30 |

||

|

450 |

18 |

273T3N |

273.05 |

355.60 |

198.70 |

264.62 |

183.80 |

||

|

500 |

20 |

298T3N |

298.45 |

372.60 |

221.30 |

290.02 |

192.20 |

||

|

550 |

22 |

298T3N |

298.45 |

372.60 |

221.30 |

290.02 |

192.20 |

||

|

Electrode |

Standard Weight of Nipples |

||||||||

|

Nominal Electrode Size |

3TPI |

4TPI |

|||||||

|

Diameter × Length |

T3N |

T3L |

T4N |

T4L |

|||||

|

inch |

mm |

lbs |

kg |

lbs |

kg |

lbs |

kg |

lbs |

kg |

| 14 × 72 | 350 × 1800 | 32 | 14.5 | - | - | 24.3 | 11 | - | - |

| 16 × 72 | 400 × 1800 | 45.2 | 20.5 | 46.3 | 21 | 35.3 | 16 | 39.7 | 18 |

| 16 × 96 | 400 × 2400 | 45.2 | 20.5 | 46.3 | 21 | 35.3 | 16 | 39.7 | 18 |

| 18 × 72 | 450 × 1800 | 62.8 | 28.5 | 75 | 34 | 41.9 | 19 | 48.5 | 22 |

| 18 × 96 | 450 × 2400 | 62.8 | 28.5 | 75 | 34 | 41.9 | 19 | 48.5 | 22 |

| 20 × 72 | 500 × 1800 | 79.4 | 36 | 93.7 | 42.5 | 61.7 | 28 | 75 | 34 |

| 20 × 84 | 500 × 2100 | 79.4 | 36 | 93.7 | 42.5 | 61.7 | 28 | 75 | 34 |

| 20 × 96 | 500 × 2400 | 79.4 | 36 | 93.7 | 42.5 | 61.7 | 28 | 75 | 34 |

| 20 × 110 | 500 × 2700 | 79.4 | 36 | 93.7 | 42.5 | 61.7 | 28 | 75 | 34 |

| 22 × 84 | 550 × 2100 | - | - | - | - | 73.4 | 33.3 | 94.8 | 43 |

| 22 × 96 | 550 × 2400 | - | - | - | - | 73.4 | 33.3 | 94.8 | 43 |

| 24 × 84 | 600 × 2100 | - | - | - | - | 88.2 | 40 | 110.2 | 50 |

| 24 × 96 | 600 × 2400 | - | - | - | - | 88.2 | 40 | 110.2 | 50 |

| 24 × 110 | 600 × 2700 | - | - | - | - | 88.2 | 40 | 110.2 | 50 |

|

Electrode Diameter |

inch |

8 |

9 |

10 |

12 |

14 |

|

mm |

200 |

225 |

250 |

300 |

350 |

|

|

Easing Moment |

N·m |

200–260 |

300–340 |

400–450 |

550–650 |

800–950 |

|

Electrode Diameter |

inch |

16 |

18 |

20 |

22 |

24 |

|

mm |

400 |

450 |

500 |

550 |

600 |

|

|

Easing Moment |

N·m |

900–1100 |

1100–1400 |

1500–2000 |

1900–2500 |

2400–3000 |

Installation Instruction

- Before installing the graphite electrode nipple,Clean dust and dirt on the surface and socket of electrode and nipple with compressed air; (see pic1)

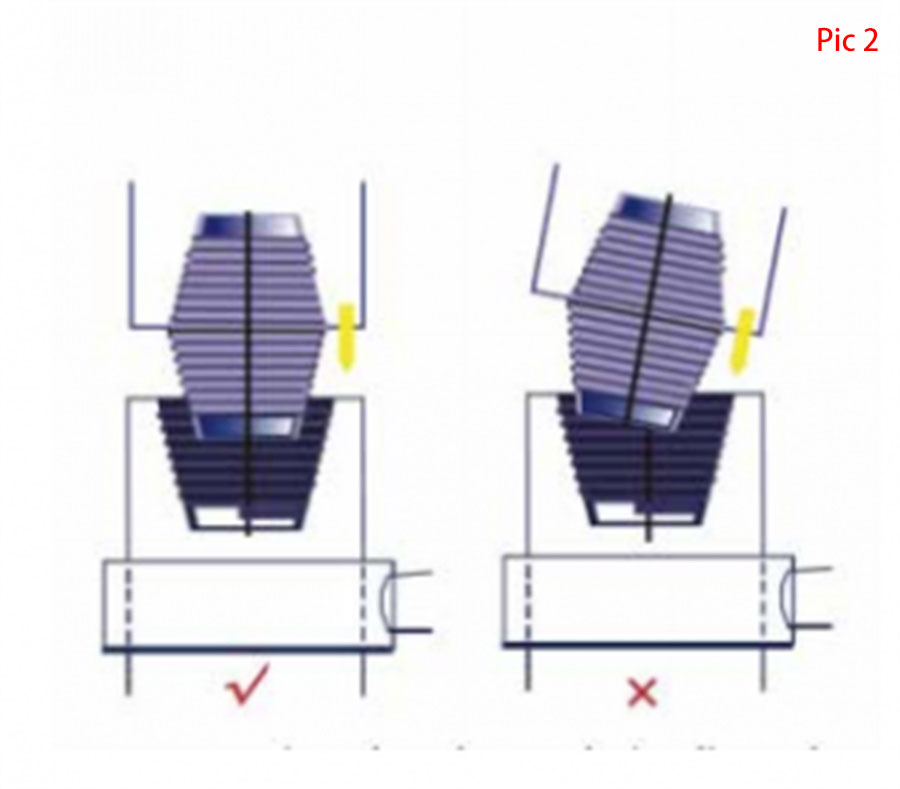

- The middle line of graphite electrode nipple should be kept consistent during two pieces graphite electrodes joint together; (see pic2)

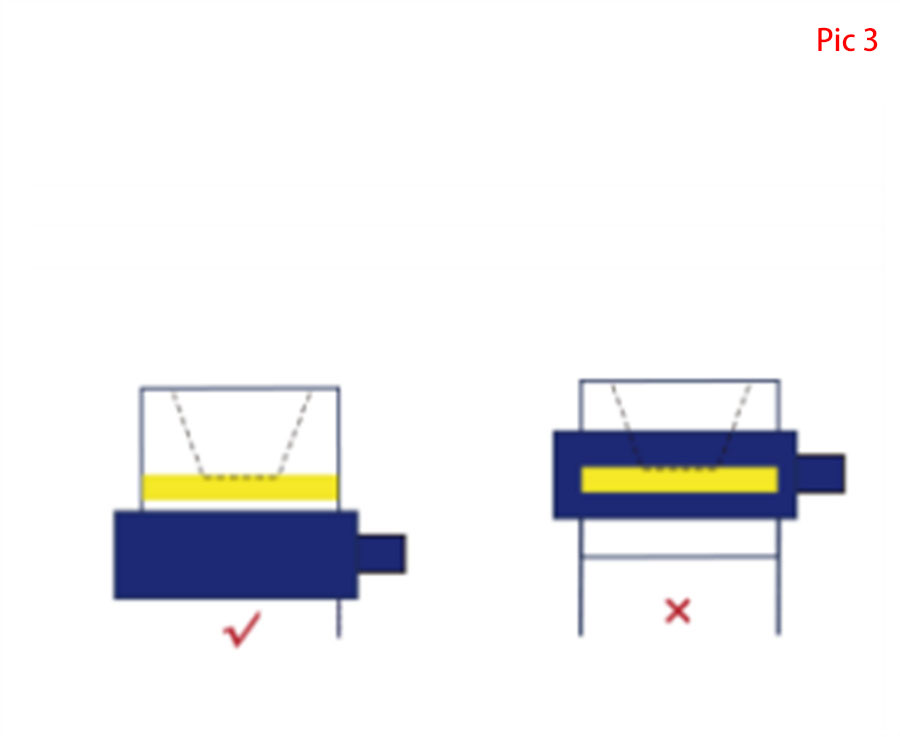

- Electrode clamper must be hold at the proper position: outside the safety lines of the higher end; (see pic3)

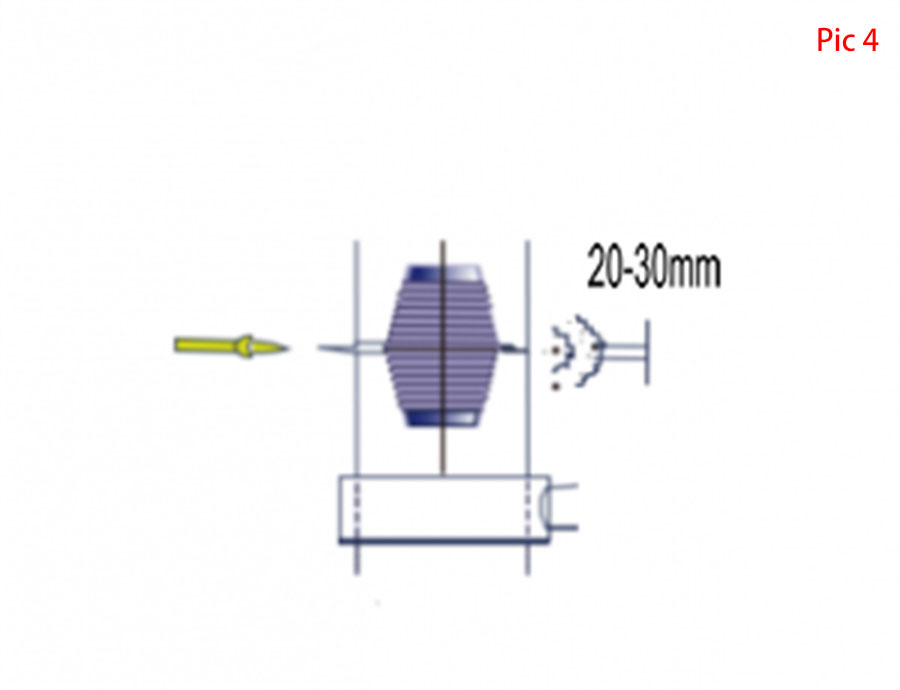

- Before tightening the nipple,ensure the nipple surface clean without dust or dirty. (see pic4)

The graphite electrode nipple is a critical component in the EAF steelmaking process. Its quality directly affects the efficiency and reliability of the process. Using high-quality nipples is essential to prevent electrode accidents and ensure a smooth and productive steelmaking process.According to industry data, over 80% of electrode accidents are caused by broken nipples and loose tripping. For Selecting the proper nipple,the below factors must be considered.

- Thermal conductivity

- Electrical resistivity

- Density

- Mechanical strength

When selecting a graphite electrode nipple, it is essential to consider its quality, size, and shape, and compatibility with the electrode and furnace specifications. By selecting the right nipple, manufacturers can improve their steel quality and reduce costs associated with downtime and poor productivity.

Including its thermal conductivity, electrical resistivity, density, and mechanical strength.