Graphite Electrode Scrap As Carbon Raiser Recarburizer Steel Casting Industry

Technical Parameter

|

Item |

Resistivity |

Real Density |

F.C |

S.C |

Ash |

V.M |

|

Data |

≤90μΩm |

≥2.18g/cm3 |

≥98.5% |

≤0.05% |

≤0.3% |

≤0.5% |

|

Note |

1.The best selling size is 0-20mm, 0-40, 0.5-20,0.5-40mm etc. | |||||

| 2.We can crush and screen according to customers' requirement. | ||||||

| 3.Large quantity and stable supplying ability according to customers' specific requirement | ||||||

Graphite Electrode Scrap Performance

- High carbon content

- Low sulfur content

- High purity

- High volatile matter

- Low ash

- High density

Description

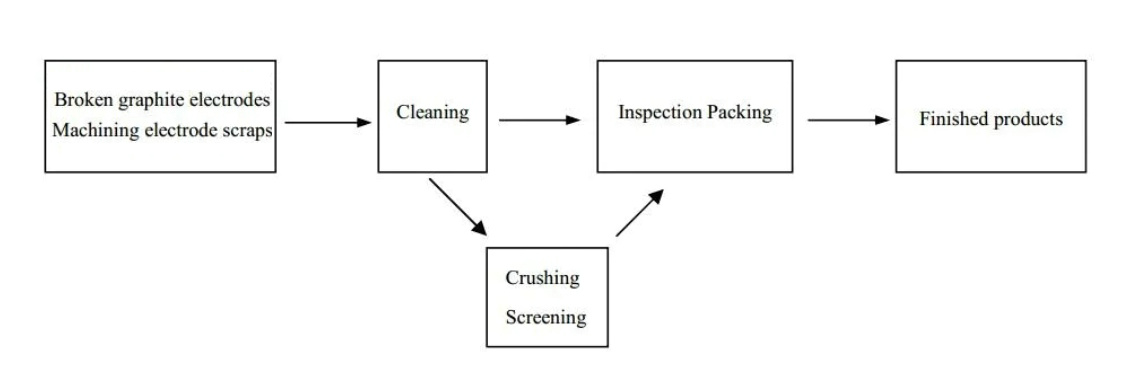

The graphite electrode scrap is coming from broken graphite electrodes,machining electrode scraps.We collect,crush,inspect and packing finally delivered to customers.

Graphite electrode scrap is commonly used in the steelmaking,metallurgy industry as a carbon raiser, reducer, foundry modifier, carbon additives,and fireproof material.

Graphite electrode scrap is available in different sizes, including powder and granules, making it perfect for a range of applications and making it highly versatile. The powder form is suitable for addition to molten metal, while granules can be used in the preparation of steel and casting materials. This versatility provides flexibility and convenience, ensuring that manufacturers can work with the material according to their preferences and requirements.

The high carbon content of graphite electrode scrap ensures effectiveness in enhancing the characteristics of steel and casting products. It also possesses excellent heat conductivity properties, making it ideal for use in electric arc furnaces. The unique material has been widely used for increasing the carbon content of steel and iron alloys for many years, and it has become increasingly popular due to its overall performance benefits.

Products Process

Application

1. As raw material of producing carbon electrodes andcathode carbon block

2. As carbon additives,carbon raiser, carbonizer in steel making and foundry

- Packed in plastic woven bags or according to customers' requirements or in loose packing

- Gufan Carbon control every process to ensure the strict quality products to satisfied every customers’ requirement.

- Gufan Carbon supply different sizes for products including powder and granules.All products can be produced according customers’ requirement.

Customer Satisfaction Guarantee

Your “One-Stop-Shop” for GRAPHITE ELECTRODE at the guaranteed lowest price

From the moment you contact Gufan, our team of experts are committed to providing outstanding service, quality products, and timely delivery, and we stand behind every product we produce.

GUFAN customer services is committed to providing exceptional customer service at every stage of the product usages,Our team supports all customers to achieve their operational and financial targets through the provision of critical support in essential areas.