Small Diameter Graphite Electrodes Rod For Electric Arc Furnace In Steel And Foundry Industry

Technical Parameter

Chart 1:Technical Parameter For Small Diameter Graphite Electrode

|

Diameter |

Part |

Resistance |

Flexural Strength |

Young Modulus |

Density |

C.T.E |

Ash |

|

|

Inch |

mm |

μΩ·m |

MPa |

GPa |

g/cm3 |

×10-6/℃ |

% |

|

|

3 |

75 |

Electrode |

7.5-8.5 |

≥9.0 |

≤9.3 |

1.55-1.64 |

≤2.4 |

≤0.3 |

|

Nipple |

5.8-6.5 |

≥16.0 |

≤13.0 |

≥1.74 |

≤2.0 |

≤0.3 |

||

|

4 |

100 |

Electrode |

7.5-8.5 |

≥9.0 |

≤9.3 |

1.55-1.64 |

≤2.4 |

≤0.3 |

|

Nipple |

5.8-6.5 |

≥16.0 |

≤13.0 |

≥1.74 |

≤2.0 |

≤0.3 |

||

|

6 |

150 |

Electrode |

7.5-8.5 |

≥8.5 |

≤9.3 |

1.55-1.63 |

≤2.4 |

≤0.3 |

|

Nipple |

5.8-6.5 |

≥16.0 |

≤13.0 |

≥1.74 |

≤2.0 |

≤0.3 |

||

|

8 |

200 |

Electrode |

7.5-8.5 |

≥8.5 |

≤9.3 |

1.55-1.63 |

≤2.4 |

≤0.3 |

|

Nipple |

5.8-6.5 |

≥16.0 |

≤13.0 |

≥1.74 |

≤2.0 |

≤0.3 |

||

|

9 |

225 |

Electrode |

7.5-8.5 |

≥8.5 |

≤9.3 |

1.55-1.63 |

≤2.4 |

≤0.3 |

|

Nipple |

5.8-6.5 |

≥16.0 |

≤13.0 |

≥1.74 |

≤2.0 |

≤0.3 |

||

|

10 |

250 |

Electrode |

7.5-8.5 |

≥8.5 |

≤9.3 |

1.55-1.63 |

≤2.4 |

≤0.3 |

|

Nipple |

5.8-6.5 |

≥16.0 |

≤13.0 |

≥1.74 |

≤2.0 |

≤0.3 |

||

Chart 2:Current Carrying Capacity For Small Diameter Graphite Electrode

|

Diameter |

Current Load |

Current Density |

Diameter |

Current Load |

Current Density |

||

|

Inch |

mm |

A |

A/m2 |

Inch |

mm |

A |

A/m2 |

|

3 |

75 |

1000-1400 |

22-31 |

6 |

150 |

3000-4500 |

16-25 |

|

4 |

100 |

1500-2400 |

19-30 |

8 |

200 |

5000-6900 |

15-21 |

|

5 |

130 |

2200-3400 |

17-26 |

10 |

250 |

7000-10000 |

14-20 |

Advantages

1.Anti-oxidation treatment for longevity.

2.High-purity,high-density,strong chemical stability.

3.High machining accuracy,good surface finishing.

4.High mechanical strength,low electrical resistance.

5.Resistant to cracking & spalling.

6.High resistance to oxidation and thermal shock.

Main Application

- Calcium carbide smelting

- Carborundum production

- Corundum refining

- Rare metals smelting

- Ferrosilicon plant refractory

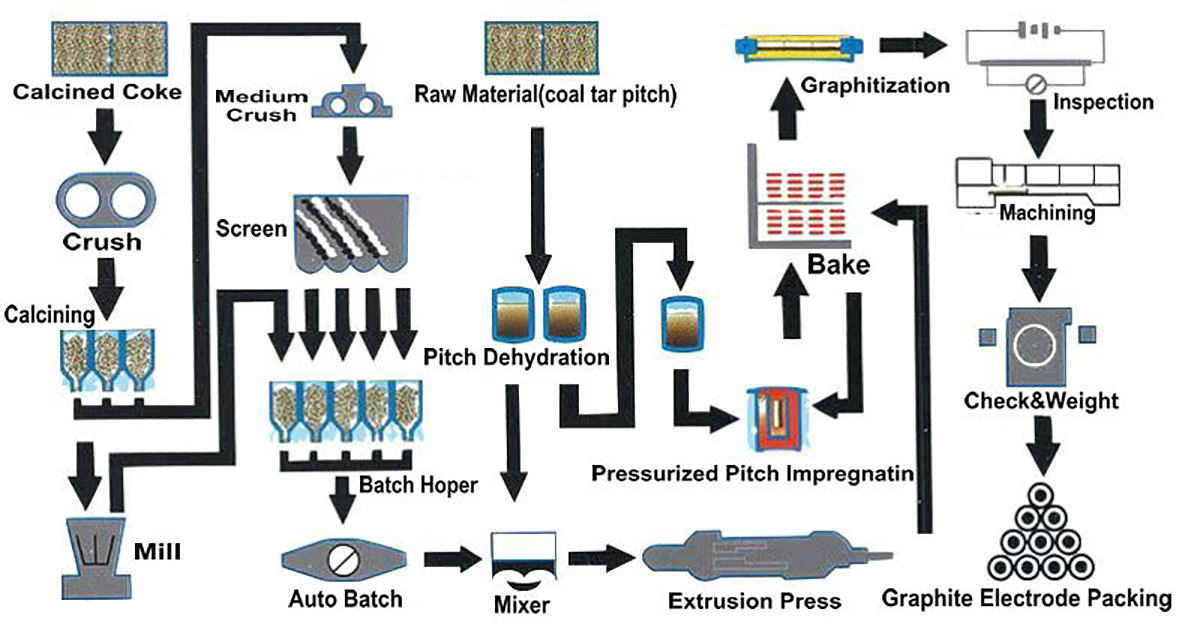

RP Graphite Electrode Production Process

Surface Quality Ruler

1.The defects or holes should not more than two parts on the graphite electrode surface, and the defects or holes size not be allowed exceed the data in table below mentioned.

2.There is no transverse crack on the electrode surface.For longitudinal crack,its length should be not more than 5% of the graphite electrode circumference,its width should be within 0.3-1.0mm range.Longitudinal crack data below 0.3mm data should be negligible

3.The width of he rough spot(black) area on the graphite electrode surface should be not less than 1/10 of the graphite electrode circumference,and the length of rough spot(black) area over 1/3 of the graphite electrode length is not be allowed.