UHP graphite electrodes are essential components in electric arc furnaces, providing the necessary electrical conductivity and thermal resistance to withstand extreme temperatures and harsh conditions. As the demand for high-quality steel and other metal products continues to grow, the importance of UHP graphite electrodes cannot be overstated.

What are UHP Graphite Electrodes?

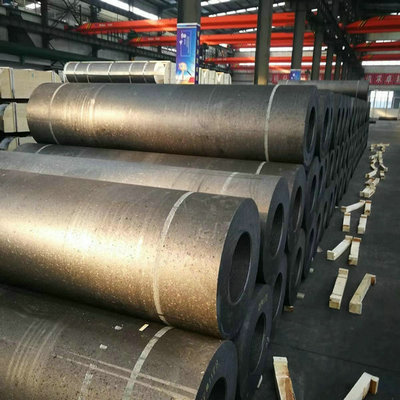

UHP graphite electrodes are ultra-high power graphite electrodes designed to withstand the rigorous conditions of electric arc furnaces. They are made from high-quality raw materials, including petroleum coke, needle coke, and coal tar pitch, which are carefully processed to achieve the desired physical and chemical properties. The resulting graphite electrodes exhibit high electric conductivity, excellent thermal stability, and low electrical resistance, making them ideal for use in electric arc furnaces.

The Role of UHP Graphite Electrodes in Electric Arc Furnaces

Electric arc furnaces are widely used in the steelmaking industry to melt scrap steel and produce high-quality steel products. UHP graphite electrodes play a crucial role in this process by providing the electrical energy necessary to initiate and sustain the arc between the electrode and the metal charge. During operation, the intense heat generated by the electric arc melts the scrap steel, while the UHP graphite electrodes transfer the electrical energy to the molten metal, contributing to the overall efficiency and performance of the furnace.

Key Features of UHP Graphite Electrodes

UHP graphite electrodes are characterized by several key features that make them well-suited for use in electric arc furnaces. These features include:

1. High graphite properties Thermal Conductivity: UHP graphite electrodes exhibit exceptional thermal conductivity, allowing them to withstand extreme temperatures without deforming or deteriorating. This property is essential for maintaining the stability and integrity of the electrodes during the steelmaking process.

2. Low Electrical Resistance: UHP graphite electrodes have low electrical resistance, which enables efficient energy transfer to the metal charge in the electric arc furnace. This low resistance contributes to the overall energy efficiency of the furnace and helps reduce operating costs.

3. Superior Mechanical Strength: UHP graphite electrodes are engineered to possess high mechanical strength and resistance to thermal shock, ensuring durability and longevity in demanding operating conditions. This mechanical resilience allows the electrodes to withstand the mechanical and thermal stresses encountered during steelmaking processes.

4. High Purity and Homogeneity: UHP graphite electrodes are manufactured to strict quality standards, ensuring high purity and homogeneity of the graphite material. This results in consistent and reliable performance, as well as minimal impurities that could affect the quality of the steel produced.

UHP Graphite Electrodes Application

UHP graphite electrodes are primarily used in electric arc furnaces for steelmaking, but they also find applications in other industrial processes that require high-temperature and high-power electrical applications. These may include the production of ferroalloys, silicon metal, phosphorus, calcium carbide, and other specialty metals and alloys. Additionally, UHP graphite electrodes are utilized in the smelting of various metals and in the production of certain chemical products where high-temperature processes are involved.

The Importance of Quality in UHP Graphite Electrodes

The quality of UHP graphite electrodes is paramount to the efficiency and performance of electric arc furnaces. Inferior or substandard electrodes can result in decreased furnace productivity, higher energy consumption, and increased maintenance costs. Therefore, it is essential for steelmakers and other industrial users to source UHP graphite electrodes manufacturers that adhere to stringent quality control measures and produce electrodes that meet industry standards.

UHP graphite electrodes are indispensable components in electric arc furnaces, playing a vital role in the production of high-quality steel and other metal products. Their high thermal conductivity, low electrical resistance, superior mechanical strength, and consistent quality make them the ideal choice for demanding industrial applications. As the steel industry and other metal-producing sectors continue to evolve, the demand for UHP graphite electrodes will remain strong, driven by the need for efficient and sustainable steelmaking processes. By understanding the significance of UHP graphite electrodes and recognizing their impact on electric arc furnace operations, steelmakers can optimize their production processes and achieve higher levels of performance and productivity.

Post time: Mar-07-2024